Products

Metal abrasive Simbi Grit Blast Media

SIMBA GRIT

Iyi midhiya ine hukasha inoshandiswa mukuputitsa nekubvisa simbi nesimbi. Steel Grit inonyatso gadzira etching pasimbi dzakaomarara kuitira kunamatira zviri nani kwejasi rinosanganisira pendi, epoxy, enamel uye rabha. Zvishandiso zvinosanganisira kugadziridza mota yenjanji, kubviswa kwekupenya, mabhiriji anoputika, zvikamu zvesimbi uye maindasitiri ekugadzira.

| Products | Steel Grit | |

| Kuumbwa Kwemakemikari | CR | 1.0-1.5% |

| C | 1.0-1.5% | |

| Si | 0.4-1.2% | |

| Mn | 0.6-1.2% | |

| S | ≤0.05% | |

| P | ≤0.05% | |

| Kuoma | Steel shot | GP 41-50HRC;GL 50-55HRC;GH 63-68HRC |

| Density | Steel shot | 7.6g/cm3 |

| Micro chimiro | Martensite chimiro | |

| Chitarisiko | Spherical Hollow particles<5% Crack particle <3% | |

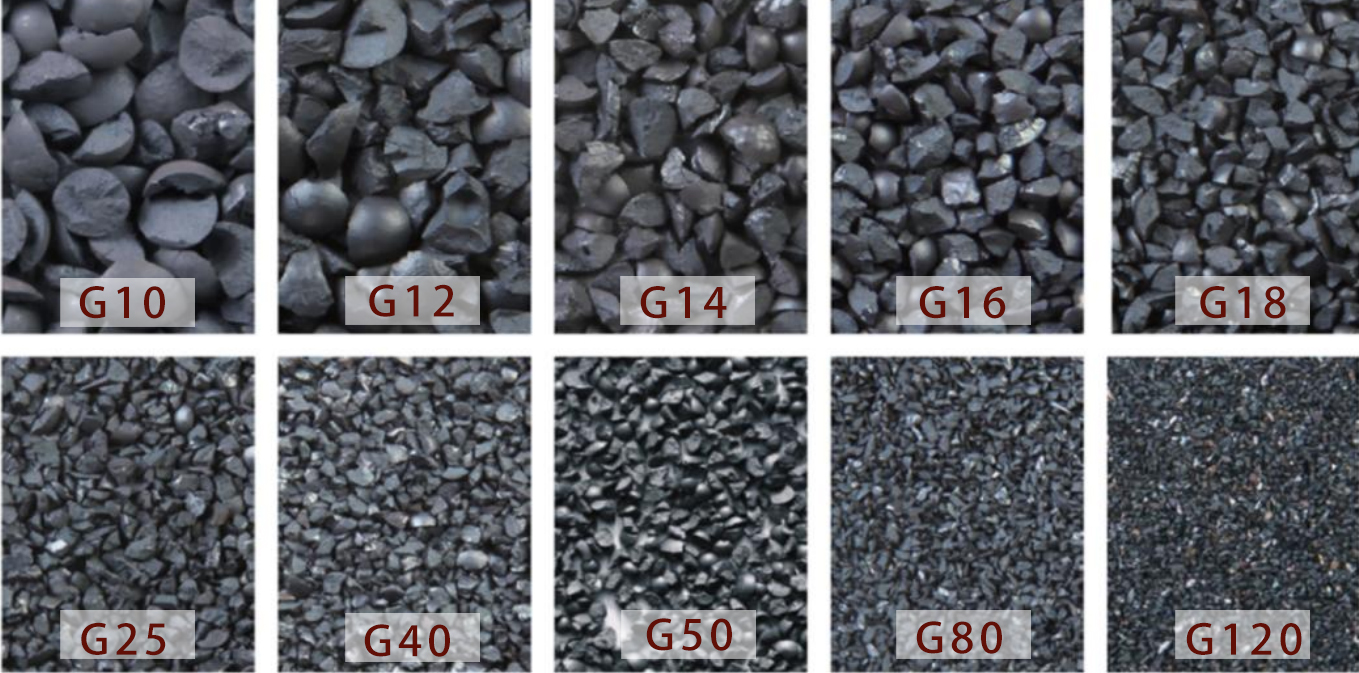

| Type | G120,G80,G50,G40,G25,G18,G16,G14,G12,G10 | |

| Diameter | 0.2mm,0.3mm,0.5mm,0.7mm,1.0mm,1.2mm,1.4mm,1.6mm,2.0mm,2.5mm | |

Steel Grit Application

1.Surface Preparation: Steel grits inoshandiswa zvakanyanya pakugadzirisa kwepamusoro musati maisa mapeji, pendi, kana zvinonamatira. Vanonyatsobvisa ngura, chiyero, machira ekare, uye tsvina kubva kune simbi, kuve nechokwadi chekunamatira kwakakodzera kwezvinhu zvinotevera.

2.Rust uye Corrosion Removal: Steel grits inoshandiswa kubvisa marara anorema, gorosi, uye mill scale kubva panzvimbo dzesimbi, kunyanya mumaindasitiri akadai sekuvaka zvikepe, kuchengetedza marine, uye kugadzirwa kwesimbi.

3.Kugadzirira kweWelding: Pamberi pekugadzirisa kana mamwe maitiro ekubatanidza, grits yesimbi inogona kushandiswa kuchenesa uye kugadzirira nzvimbo, kuve nechokwadi kuti yakasimba uye yakachena weld joints.

4.Concrete uye Stone Surface Kugadzirira: Simbi grits inogona kushandiswa kuchenesa uye kugadzirira kongiri uye matombo ematombo, akadai semapurojekiti ekudzorera, uko kubviswa kwezvipfeko zvekare, tsvina, kana kusvibiswa kunokosha.

5.Shot Peening: Nepo mapfuti esimbi ari kunyanya kushandiswa kupfurwa peening, simbi grits inogona zvakare kushandiswa kuita izvi. Shot peening inosanganisira kubhomba pamusoro penzvimbo ine abrasive particles kukonzeresa compression stress, izvo zvinowedzera simba rechinhu uye kuramba kuneta.

6.Deburring uye Deflashing: Steel grits inoshandiswa kubvisa burrs, mitsara inopinza, uye zvinhu zvakawandisa kubva kune zvikamu zvesimbi, kunyanya mumagadzirirwo ekugadzira apo kunyatso uye kutsetseka kunodiwa.

7.Foundry Applications: Steel grits inoshandiswa mumitsva yekuchenesa nekugadzira nzvimbo dzekukanda, mold uye core kubvisa, uye general metal surface treatment. 8.Surface Profileing: Steel grits inoshandiswa kugadzira mamwe maitiro epamusoro, kunyanya mumaindasitiri akaita sekuvaka uye kuvaka ngarava. Aya ma profiles anonatsiridza kunamatira kunamatira uye anopa zvirinani kubata kune anti-kutsvedza nzvimbo.

9.Stone Kucheka uye Kuchera: Mukuvaka uye zvivako zvekugadzira, simbi yesimbi inoshandiswa pakucheka uye kuisa matombo nezvimwe zvinhu zvakaoma, kugadzira maitiro akaoma uye mapatani.

10.Oil uye Gasi Indasitiri: Simbi grits inoshandiswa kugadzirira pamusoro pemafuta uye gasi indasitiri, sekuchenesa mapaipi, matangi, uye zvimwe midziyo.

11.Automotive Industry: Steel grits inogona kushandiswa kubvisa pendi uye machira kubva kune zvikamu zvemotokari, kugadzirira nzvimbo dzekugadzirisa kana kudzorerwa.

Izvo zvakakosha kuti uzive kuti kusarudzwa kweiyo yakakodzera simbi grit saizi, kuoma, uye zvimwe zvinongedzo zvinoenderana neiyo chaiyo application uye inodiwa pamusoro pekupedzisira. Iyo abrasive zvimiro zvesimbi grits inovaita maturusi akakosha emabasa anoda kubviswa kwakasimba kwezvinhu uye kugadziridzwa kwepasi.

Kubvunza Kwako

Kana uine mibvunzo.Ndapota inzwa wakasununguka kutibata nesu.