Products

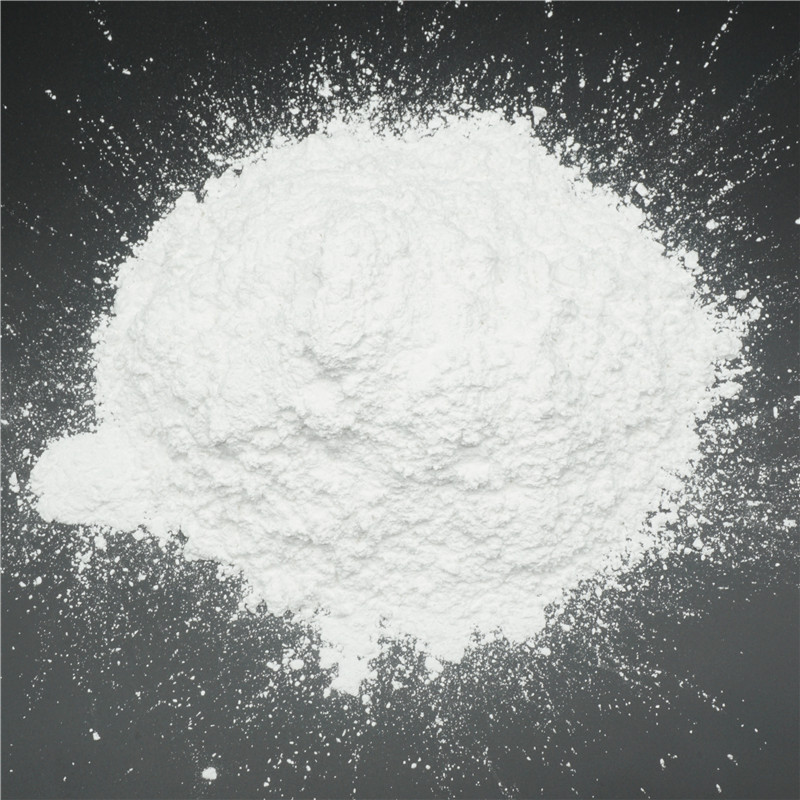

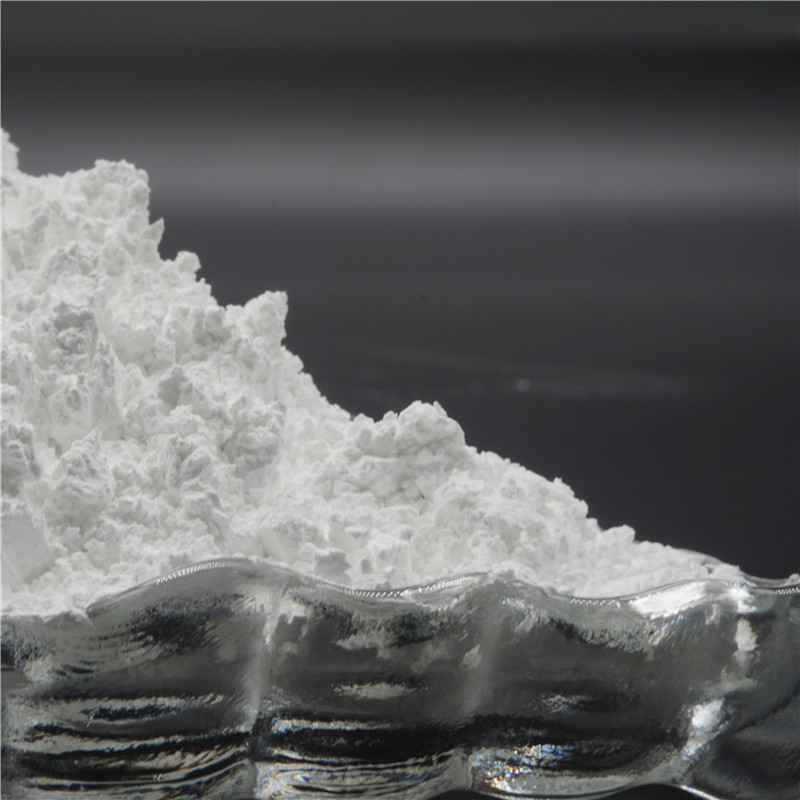

Platelet Calcined Alumina Powder

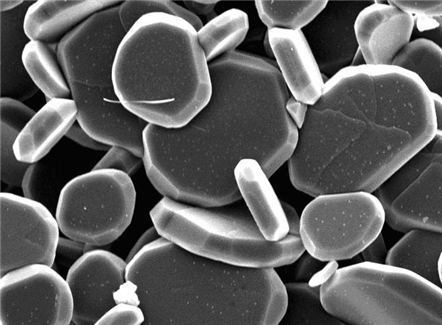

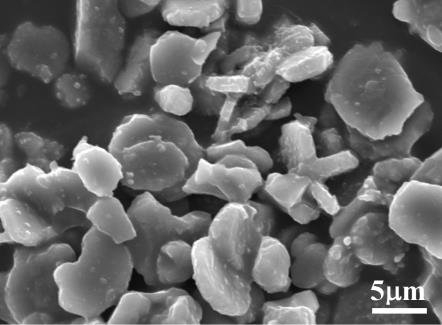

Plate Calcined Alumina polishing poda inogadzirwa neyemhando yepamusoro indasitiri alumina poda seyakabikwa, uye inogadziriswa neyakagadzirwa maitiro. Chimiro chekristaro cheyakagadzirwa alumina polishing poda ine hexagonal flat senge tabular chimiro, saka inonzi Platelet Alumina kana Tabular Alumina.

Platelet Alumina imhando yemhando yepamusoro alumina mhando abrasive poda, inoumbwa neplate-shaped crystal yeAl2O3 nekuchena kweinopfuura 99.0%. Iyo ine yakanakisa inodzivirira kupisa zvimiro pamwe nekuve inert yemakemikari, uye haina corrod neaid kana alkaline. Sezvo kugovaniswa kwesaizi yePlatelet Alumina yakadzorwa zvakasimba, inogona kuburitsa yakanyatso kupfekwa pamusoro, ichipa kushanda kwepamusoro seabrasive. Iine huwandu hwakakura hwemashandisirwo, Platelet Alumina ihupfu inoputika inokwanisa kuita zviuru zvemabasa.

Tabular alumina poda

Tabular alumina poda

Yakajairika yakatarwa yehukuru

| Particle | Particle Kugovera (μm) | |||

| Maximum particle | Chikamu saizi | Chikamu saizi | Chikamu saizi | |

| 45 | <82.9 | 53.4± 3.2 | 34.9± 2.3 | 22.8± 1.8 |

| 40 | <77.8 | 41.8± 2.8 | 29.7± 2.0 | 19.0± 1.0 |

| 35 | <64.0 | 37.6± 2.2 | 25.5± 1.7 | 16.0± 1.0 |

| 30 | <50.8 | 30.2± 2.1 | 20.8± 1.5 | 14.5± 1.1 |

| 25 | <40.3 | 26.3± 1.9 | 17.4± 1.3 | 10.4± 0.8 |

| 20 | <32.0 | 22.5± 1.6 | 14.2± 1.1 | 9.00±0.80 |

| 15 | <25.4 | 16.0± 1.2 | 10.2± 0.8 | 6.30±0.50 |

| 12 | <20.2 | 12.8± 1.0 | 8.20±0.60 | 4.90±0.40 |

| 9 | <16.0 | 9.70±0.80 | 6.40±0.50 | 3.60±0.30 |

| 5 | <12.7 | 7.20±0.60 | 4.70±0.40 | 2.80±0.25 |

| 3 | <10.1 | 5.20±0.40 | 3.10±0.30 | 1.80±0.30 |

Quality Standard

| Rudzi rwechigadzirwa | Specific Gravity | ||||

| Al2O3 | SiO2 | Fe2O3 | Na2O | ||

| 3µm-45µm | >3.90 | >99.0 | <0.20 | <0.10 | <1.00

|

Alumina Powder Zvakanaka

1. Enzanisa nehumwe hupfu hwetabular, iyo tabular alumina poda ine yakanakisa kusanganisa zvinhu. Zvakadai seyakanyanya kunyungudika, kuoma kwakasimba, kusimba kwemagetsi, kunaka kupfeka kusagadzikana, makemikari kuramba, oxidation kuramba uye kupisa kupisa nezvimwe.

2. Flat sheet shape inoita kuti friction iwedzere, inovandudza kukuya nekukurumidza, izvi zvinogona kuderedza kuwanda kwemashini ekukuya, kushanda uye nguva yekukuya.

3. Flat sheet shape inoita kuti chinhu chinokuya chisave nyore kukwenya, chiyero chezvigadzirwa zvemhando yepamusoro chinogona kuwedzera 10% -15%. Semuenzaniso, chiyero cheanokwanisa semiconductor silicon wafer inogona kusvika ku96% kana kupfuura.

4. Iine maitiro maviri e nano uye micro powders, basa repamusoro rine mwero, kwete chete rinogona kunyatsobatanidza nemamwe mapoka anoshanda, asiwo hazvisi nyore kuunganidza uye kufambisa kupararira kunobudirira.

5. Iine yakanaka adhesion, yakakosha kudzivirira mhedzisiro uye kugona kuratidza chiedza.

6. Iyo tabular alumina poda inenge yakajeka, isina ruvara, uye ine nzvimbo yakati sandara uye yakatsetseka. Makristasi akanyatsogadzirwa ane hexagoni nguva dzose.

7. Iyo tabular alumina poda inogona kugadzirwa muhupfu hwekupenya.

1. Indasitiri yemagetsi: kukuya uye kupukuta kwe semiconductor monocrystalline silicon wafers, quartz quartz crystals, compound semiconductors (crystalline gallium, phosphating nano).

2. Indasitiri yegirazi: kukuya uye kugadzirisa kwekristaro, girazi requartz, kinescope girazi shell screen, optical glass, liquid crystal display (LCD) girazi substrate, uye quartz crystal.

3. Indasitiri yekuputira: machira akakosha uye mafirita ekupfapfaidza plasma.

4. Metal uye ceramic processing industry: precision ceramic materials, sintered ceramic raw materials, high-grade high-temperature coatings, nezvimwewo.

Kubvunza Kwako

Kana uine chero mibvunzo.Ndapota inzwa wakasununguka kutibata nesu.