Iwo mashiripiti epasirese microscopic, anokutora iwe kutsanangura nano-electroplating

Munguva yekukurumidza kukura kwesainzi uye tekinoroji,nanotechnology yakaita senyeredzi itsva yakajeka, inopenya munzvimbo dzakasiyana-siyana dzemuganhu. Seyakasimukira yemagetsi tekinoroji, nano-electroplating inosanganisa nanotechnology neyechinyakare electroplating maitiro. Nekuunza nanomaterials kana kudzora nanostructure yejasi panguva ye electroplating process, kupfekedza nekuita kwakanakisa kunowanikwa. Iyo musimboti ndeye kushandisa yakakosha zvimiro zve nanoparticles, senge yakakwira chaiyo nzvimbo, yakakwirira chiitiko uye yakasarudzika yemuviri uye kemikari zvivakwa, kuvandudza mashandiro eiyo electroplating layer. Munguva ye electroplating process, nanoparticles inogona kuparadzirwa mune electroplating mhinduro sezvinowedzera. Sezvo nzira ye electroplating ichienderera mberi, iyo nanoparticles ichaiswa pamusoro peiyo substrate uye inogadzira yakasanganiswa coating nemamwe electroplating ions. Uku kupfekedza hakungove nekudzivirira uye kushongedza mabasa echinyakare electroplating coatings, asi zvakare ine yakasarudzika mabhenefiti ekuita.

Ⅰ. Yakanyanya kuita zvakanakira nano-electroplating coatings

1. Kuoma uye kupfeka kuramba

Nekuda kwekuwedzera kwe nanoparticles, kuoma kweiyo electroplating coating kwakagadziridzwa zvakanyanya. Semuenzaniso, mushure mekuwedzera nano-diamond zvimedu kune yechinyakare nickel-phosphorus electroplating, kuomarara kwejasi kunogona kuwedzerwa kakawanda kana kunyange makumi enguva. Uku kuomarara kwepamusoro-soro kune tarisiro yakafara yekushanda mukugadzira michina, aerospace, kugadzira mota uye mamwe minda. Inogona kunyatso kudzikisa kupfekedzwa kwemechini zvikamu uye kuwedzera hupenyu hwesevhisi yemidziyo, uku ichivandudzawo kurongeka uye kuvimbika kwemidziyo.

2. Corrosion resistance

Kuramba kwecorrosion kwenano-electroplating coatings kwakagadziridzwawo zvakanyanya. Nanoparticles inoumba yakakosha microstructure mukupfeka. Ichi chimiro chinogona kunyatso kuvharira kupinda kweiyo corrosive media, nekudaro ichivandudza corrosion resistance yejasi. Semuyenzaniso, iyo yekupotera inoumbwa necomposite electroplating ye nano-ceramic particles uye simbi ions ine kanoverengeka kana kunyange kakapetwa kakapetwa kanokwirira kusimba kupfuura echinyakare electroplating coatings. Uku kupfekedza kunogona kushandiswa zvakanyanya muinjiniya yemugungwa, midziyo yemakemikari, zvigadzirwa zvemagetsi uye mamwe minda kuti ipe nguva refu yekudzivirira-kuora kudzivirira kwemidziyo.

3. Optical properties

Nano-electroplating coatings anewo akasiyana optical properties. Nekuda kwehukuru mhedzisiro ye nanoparticles, kana chiedza chikavhenekerwa kumusoro kwejasi, kupararira kwakakosha, kunyura uye kufungidzira kunoitika. Semuenzaniso, iyo coating inoumbwa necomposite electroplating ye nano-silver particles uye simbi ions inogona kuratidza yakasarudzika maoptical mhedzisiro, senge shanduko yeruvara uye kuwedzera kupenya. Uku kupfekedza kunogona kuiswa kune optical zvishandiso, zvekushongedza uye mamwe minda, ichiwedzera yakasarudzika yekuona maitiro kune zvigadzirwa

4. Zvinhu zvemagetsi

Zvinhu zvemagetsi zve nano-electroplating coatings zvakagadziridzwawo zvakanyanya. Mamwe nanoparticles ane yakakosha conductivity kana semiconductor zvivakwa. Pavanenge vaiswa electroplated nesimbi ions, vanogona kugadzira coatings ane chaiwo magetsi zvinhu. Semuyenzaniso, iyo coating inoumbwa necomposite electroplating ye nano-carbon tubes uye simbi ions ine yakanaka conductivity uye electromagnetic shielding properties. Uku kupfekedza kunogona kuiswa kumidziyo yemagetsi, midziyo yekutaurirana uye mamwe minda kuvandudza kuenderana kwemagetsi uye masaini ekufambisa kuita kwemidziyo.

Ⅱ. Nzvimbo huru dzekushandisa dze nano-electroplating

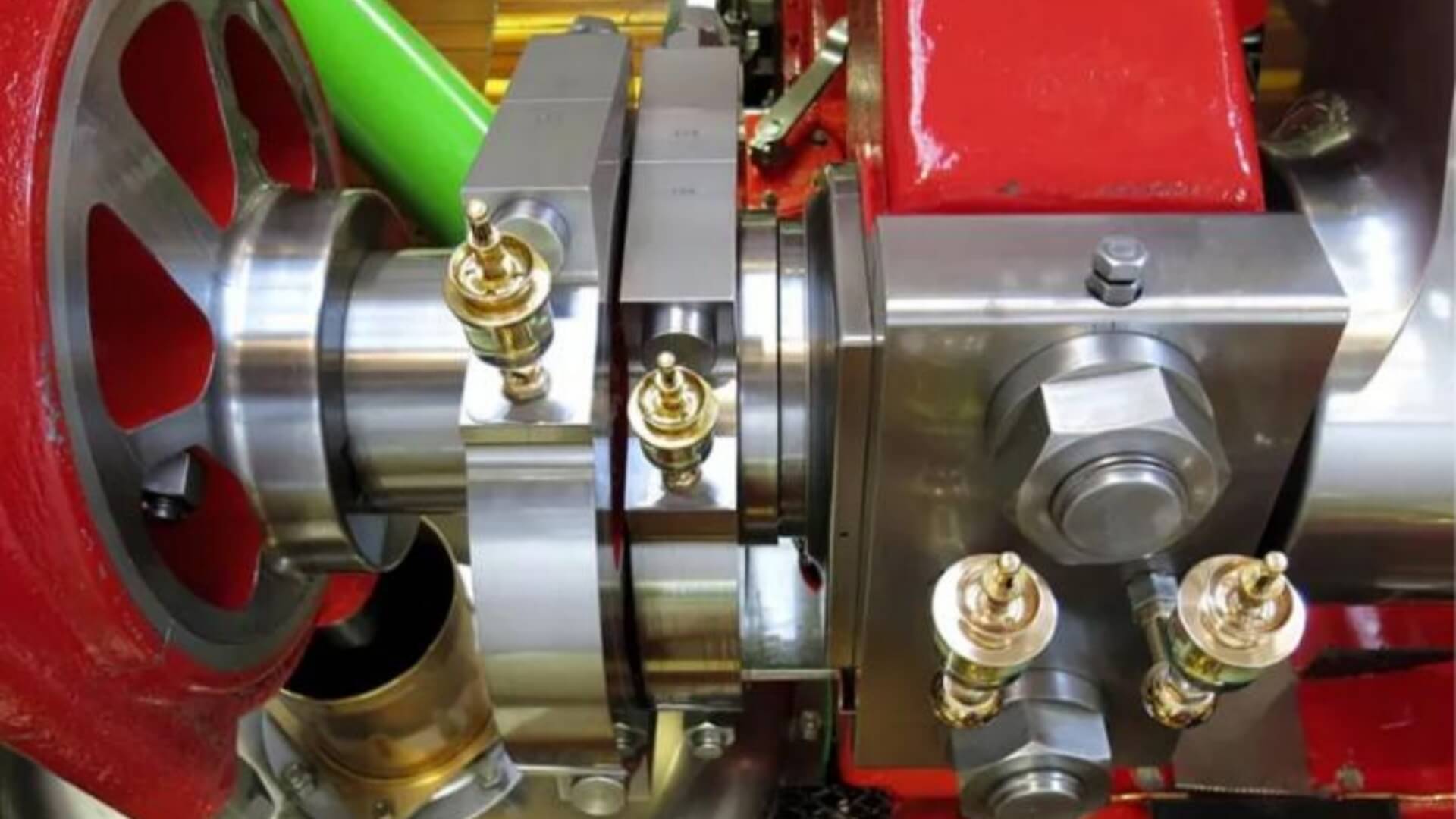

1. Mechanical kugadzira

Nekuda kwekuwedzera kwe nanoparticles, kuoma kweiyo electroplating coating kwakagadziridzwa zvakanyanya. Semuenzaniso, mushure mekuwedzera nano-diamond zvimedu kune yechinyakare nickel-phosphorus electroplating, kuomarara kwejasi kunogona kuwedzerwa kakawanda kana kunyange makumi enguva. Uku kuomarara kwepamusoro-soro kune tarisiro yakafara yekushanda mukugadzira michina, aerospace, kugadzira mota uye mamwe minda. Iyo inogona kunyatso kudzikisa kupfeka kwemechini zvikamu uye kuwedzera hupenyu hwesevhisi yemidziyo, ukuwo ichivandudza iko kurongeka uye kuvimbika kwemidziyo.

2. Muchadenga

Munda wemuchadenga une zvakanyanyisa kuita zvinodiwa zvezvishandiso, zvinoda simba rakawanda, kuomarara kwepamusoro, kupfeka kwepamusoro, kuramba kwecorrosion uye zvimwe zvivakwa. Nano-electroplating coatings inogona kusangana nezvinodiwa izvi uye inoshandiswa kugadzira zvikamu zvejini yeaerospace, majasi epamusoro endege, etc. Semuenzaniso, machira akaumbwa necomposite electroplating ye nano-ceramic particles uye simbi ions anogona zvinobudirira kuvandudza kupfeka kuramba uye kupisa kwekushisa kwezvikamu zvejini, uyewo kuderedza uremu hwezvikamu nekuvandudza kushanda kwemafuta uye kushanda kwendege.

3. Zvigadzirwa zvemagetsi nemagetsi

Mumunda wemagetsi nemagetsi emagetsi, nano-electroplating coatings inogona kushandiswa kugadzira yakakwirira-performance zvikamu zvemagetsi uye mabhodhi edunhu. Semuenzaniso, mabhanhire akaumbwa necomposite electroplating ye nano-silver particles uye simbi ions ine yakanaka conductivity uye antioxidant zvinhu uye inogona kushandiswa kugadzira yakakwirira-performance conductive circuits uye connectors. Uye zvakare, nano-electroplating coatings inogona zvakare kushandiswa kugadzira magetsi ekudzivirira zvinhu kudzivirira kukanganiswa kwemagetsi uye kugadzirisa kuvimbika kwemidziyo yemagetsi.

4. Indasitiri yemotokari

Indasitiri yemotokari ndeimwe yenzvimbo dzakakosha dze nano-electroplating application. Nano-electroplating coatings inogona kushandiswa kugadzira zvikamu zveinjini yemotokari, brake system parts, etc. Semuenzaniso, nano-body surface coatings, machira akaumbwa ne composite electroplating ye diamond particles uye ions yesimbi inogona kunyatso kuvandudza kusakara uye kusagadzikana kwekudzivirira kwejini piston mhete, nokudaro kuvandudza hupenyu hwebasa uye kushanda kwejini. Panguva imwecheteyo, nano-electroplating coatings inogona kushandiswawo kushongedza nekudzivirira kwemuviri wemotokari, kuvandudza kupenya uye kushora kwemuviri uye kuwedzera hupenyu hwebasa remota.